Building the Nosecone/capsule

|

|

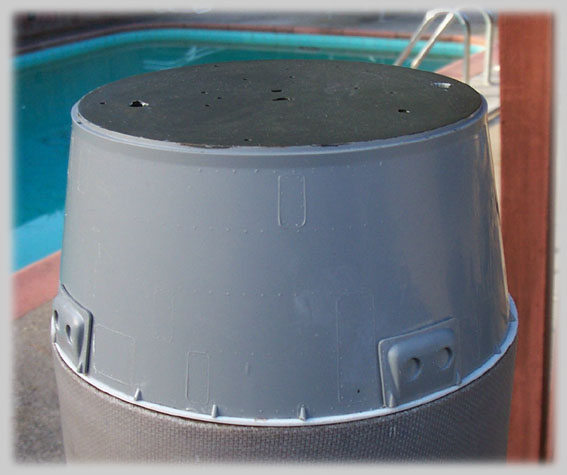

| The first step was to make the the lower service module

fit into the end cap pf the mailing tube. This was done by removing all the

detail parts and grinding down the outer edge a bit, then doing the same to the

inner edge of the tube cap. I was then able to fit the service module down into

the recessed part of the tube cap and glued them together.

|

|

|

|

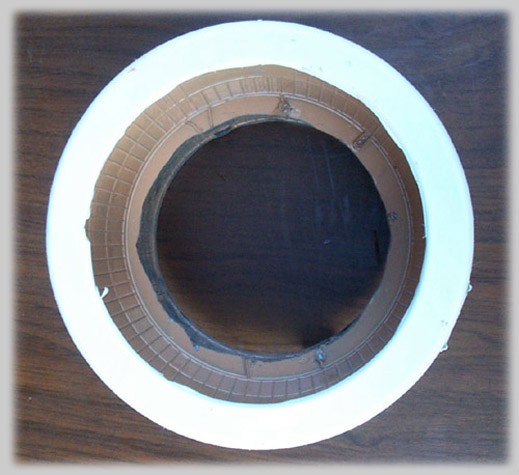

| I then built up the lower service module

to match the outer lip of the cap using Bondo and gluing the detail parts back

on. I removed all the inside parts and cut out the top out of the lower service module piece and voilá, a service module that perfectly fits the tube.

|

|

|

|

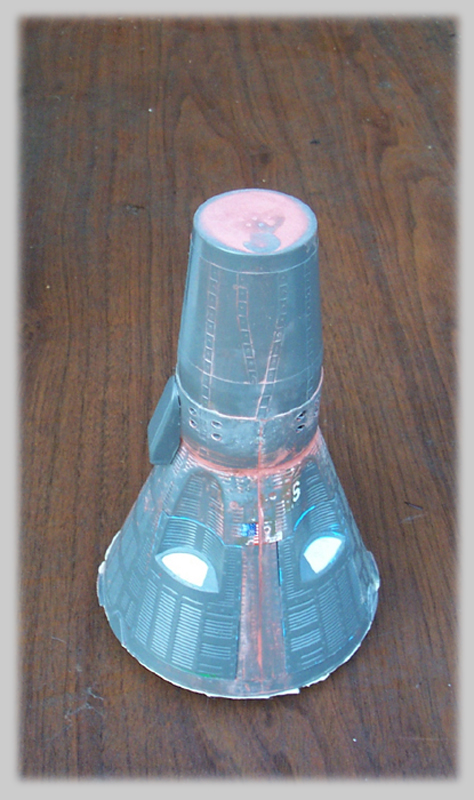

| Now on to the capsule. I drilled a hole in the top and poured in 2 ounces of

lead shot and epoxy then I reinforced and filled all the cracks/seams with Bondo

spot putty and masked it off for paint. Here are the 2 boys ready to get sealed

into their capsule.

|

|

|

|

| I drilled several holes into the heat shield before I glued the capsule to

the service modules so that when I layered the glass over it the epoxy could

drip in and make a stronger bond (well that is the theory anyway) and here it is

all assembled and ready for glassing.

|

|

|

|

|

| I put three strips of fiberglass in to help insure that the capsule stays attached, they also cover the joint for the two service module pieces so this thing should hold together just great. I added some bolts to help with bulkhead attachment but I still needed to add a little more weight so I foam filled it and added 4 ounces of lead shot to the foam before it cured. I then both painted the foam and filled the bolt hole with epoxy and attached the bulkhead. The nosecone is now complete and weighing in at 1.25 pounds. | ||